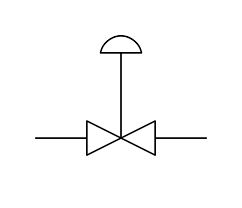

Butterfly valves are crucial in regulating flow across various industries. These versatile valves are governed by specific standards to ensure optimal performance. Prominent among these standards are those set by the American Water Works Association (AWWA), the California Air Resources Board (CARB), and the American Petroleum Institute (API).

This article delves into the key standards for butterfly valves. We will discuss AWWA butterfly valves, CARB butterfly valves, and API 609 butterfly valves. You will also know their critical safety requirements. After reading this post, you will be able to determine which butterfly valves best suit your industry.

AWWA Butterfly Valve

Overview of AWWA Standards

The AWWA butterfly valve standards may refer to AWWA C504 and AWWA C516. They are pivotal for ensuring the efficient functioning of valves in water systems. These standards cover design, material, and performance requirements. The emphasis is on durability and long-term reliability in potable water and wastewater applications.

Design Requirements for AWWA Butterfly Valves

AWWA butterfly valves are expected to exhibit superior resistance to corrosion. They can also maintain precise sealing capabilities and endure high flow rates.

The valves are typically rubber-seated and designed for ease of maintenance. What aspects of butterfly valves must comply with the AWWA standards? These are the following:

- Dimensions

- Pressure ratings

- Operating mechanisms

The goal is to ensure seamless integration into municipal water systems.

Applications in Water Treatment and Municipal Water Supply

AWWA butterfly valves are used extensively in various industries. These include municipal water systems, wastewater treatment facilities, and irrigation. This is because these valves can handle large volumes of water with minimal energy loss.

CARB Butterfly Valve: California Air Resources Board Standards

Overview of CARB Standards

The California Air Resources Board (CARB) sets stringent emissions regulations. These are primarily aimed at reducing air pollution. While CARB standards primarily focus on vehicle emissions and industrial processes, their relevance extends to valve technologies. This ensures that equipment minimizes fugitive emissions.

CARB Butterfly Valve Application Requirements

A CARB butterfly valve must meet specific leak-tightness criteria. The latter is needed to comply with emission reduction mandates. Such valves are crucial in industries where controlling volatile organic compounds (VOCs) is essential. These industries may include chemical processing and petrochemical manufacturing.

API 609 Butterfly Valve: American Petroleum Institute Standards

Overview of API 609 Standard

The API 609 butterfly valve complies with another kind of valve standard. It typically governs valves used in high-pressure and high-temperature environments. These may refer to oil, gas, and petrochemical industries. The valve specifies performance requirements for both soft-seated and metal-seated butterfly valves.

Technical Requirements for API 609 Butterfly Valves

API 609 valves must handle extreme conditions. The valves are equipped with features as shown below

- Tight shut-off capabilities

- Corrosion resistance

- Fire-safe designs

The demands of API 609 are rigorous. As such, API 609 valves are made from stainless steel and specialized alloys.

Safety and Reliability of API 609 Valves

Safety is a cornerstone of the API 609 butterfly valve standard. The valves are designed to ensure reliable operation in critical systems. Additionally, the valves minimize risks of leaks or failures under pressure. Their robust construction also supports long-term use in demanding environments.

What is the Standard API for Butterfly Valve?

Overview of API 607 Standard

The API 607 standard focuses on fire-safe testing for valves used in flammable environments. Butterfly valves are also expected to comply with it.

If a valve has API 607 certification, it means it is equipped with solid construction. The valve is believed to demonstrate the ability to maintain integrity and sealing capabilities. This is especially true during and after exposure to fire.

Features of API 607 Butterfly Valves

Key features of an API 607 butterfly valve are the following:

- Fire-resistant materials

- Secondary sealing mechanisms

- Enhanced durability

These valves are essential in environments where fire safety is paramount. Examples are refineries and offshore platforms.

Fire Testing and Applications

The fire testing procedures outlined in API 607 are essential. This is because they determine if a valve can withstand extreme temperatures without compromising safety. Applications include oil and gas processing facilities, chemical plants, and energy infrastructure.

Comparing Different Standards: AWWA, CARB, API

While all these standards focus on ensuring performance and safety, their objectives differ:

- AWWA butterfly valves prioritize water systems and emphasize corrosion resistance and durability.

- CARB butterfly valves target emissions control, focusing on minimizing leaks and fugitive emissions.

- API 609 butterfly valves are designed for high-pressure, high-temperature environments, with stringent requirements for fire safety and reliability.

Which Should You Use?

Selecting the right butterfly valve standard depends on your specific application needs:

- AWWA Butterfly Valves

Choose these valves if your business deals with municipal water supply, wastewater treatment, and irrigation systems. Their design ensures corrosion resistance. They also display efficiency in handling large water volumes.

- CARB Butterfly Valves

These valves are perfect for industries focused on emissions control. Examples are those involved in chemical processing and refining. Select these valves to comply with strict environmental regulations.

- API 609 Butterfly Valves

The last class of valves is best suited for high-pressure and high-temperature applications. These include oil, gas, and petrochemical industries. Valves with API 609 rating ensure safety and reliability in critical operations.

For fire-safe applications, consider valves certified under API 607. The reason behind this is that they provide essential protection in flammable environments.

What Standards Do the Valves Purchased by Gowin Meet?

Gowin’s valves meet a wide range of international standards. In turn, this valve manufacturer ensures their valves are suitable for diverse applications. The company’s compliance with API standards, including API 6D and API 607, highlights its dedication to safety, quality, and reliability. Gowin’s API-certified butterfly valves are integral to various industries. They have been used extensively for oil and gas projects, chemical plants, and power generation systems worldwide.

Conclusion

Industry standards such as those by AWWA, CARB, and API play essential roles in regulating purposes. They are utilized to determine the design, performance, and safety of butterfly valves. These standards have been utilized to guarantee safety in different applications. Some of them are found in water treatment, emissions control, and high-pressure oil and gas systems.

Research

What is an awwa butterfly valve? by POV valve (https://povbutterflyvalve.com/what-is-an-awwa-butterfly-valve/)

Study on characteristics and performance of butterfly valve using numerical methods – A review; K. Yuvaraj and G. Arun Kumar; 2022 (https://pubs.aip.org/aip/acp/article-abstract/2460/1/030004/2825198/)