Ensuring safety and efficiency in industrial processes is important. Choosing the right Emergency Shutdown Valve is crucial. An ESD ball valve, often referred to as an emergency shutdown valve, plays a critical role in preventing hazardous situations. It is done by stopping the flow of gas, liquids, or other substances in case of an emergency. The decision on which ESD ball valve to use depends on several factors.

This guide will help you understand how to choose the best ESD valve for your needs. Emphasizing the importance of selecting the right shutdown valve and maintaining it for optimal safety.

What is an ESD Ball Valve?

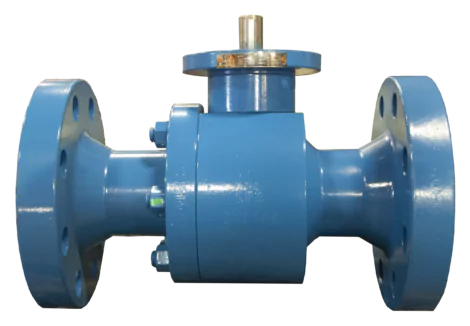

An ESD valve, or emergency shutdown valve, is a key safety device. It is designed to quickly halt the flow of a fluid in an emergency. These valves are used in many industries. This includes oil and gas, chemical processing, power generation, and water supply. This is used to protect equipment, personnel, and the environment. They are often automated with an ESD valve actuator to ensure they close or open rapidly without the need for manual intervention.

Understanding the Role of ESD Ball Valves

ESD ball valves are specifically designed to act quickly in the event of a dangerous scenario. They use a spherical ball with a hole through it that rotates to block or allow fluid flow. Ball valves are ideal for emergency shutdown operations. This is due to their fast response time and ability to provide a tight seal when needed. The shutdown valve needs to be both reliable and robust to operate effectively under extreme pressure, high temperatures, or corrosive environments.

Key Factors to Consider When Choosing an ESD Ball Valve

Choosing the right ESD ball valve for your system involves evaluating several important factors:

| Factor | Description |

| Valve Type | Ball valves for fast shut-off |

| Pressure Class | Match with system pressure |

| Temperature | Use heat-resistant materials |

| Material | Choose corrosion-resistant alloys |

| Actuator Type | Pneumatic, electric, or hydraulic options |

Valve Type

Not all valves are suitable for emergency shut-off. For emergency scenarios, ball valves are preferred due to their quick closing times. They are especially good for isolating flow because they only require a 90-degree turn to close completely. Unlike gate valves or globe valves, which take longer to operate.

Pressure Class

The pressure class of an ESD valve is critical for ensuring it can withstand the conditions of the system it is installed. Always verify the valve’s pressure class to make sure it matches the system’s operating pressure. If a valve with a lower pressure class is installed in a high-pressure system, it can lead to failure and possible hazardous incidents.

Temperature

The valve’s materials must be suitable for the operating temperature of the process. Chemical plants and power stations have high-temperature environments. Selecting a valve that can handle extreme heat in these settings is essential. Some emergency valve shut off are made from special alloys that resist high temperatures, while others may have coatings to enhance performance.

Material of Construction

Choosing the right materials for the emergency shut-off valve is critical. Most especially if the valve is exposed to corrosive substances or harsh chemicals. Common materials include stainless steel, carbon steel, and special alloys that are resistant to corrosion. Corrosion-resistant materials are a must to ensure the longevity of the shutdown valve. This is important for industries like oil and gas or chemical processing.

Actuator Type

The ESD valve actuator is the component that controls the opening and closing of the valve. Depending on your needs, you can choose between pneumatic, electric, or hydraulic actuators. Pneumatic actuators are often preferred for their fast response times. However electric or hydraulic options may be used for specific applications. The SD valve actuator should be chosen based on the speed and precision required by the system.

Maintenance and Testing

Regular maintenance and testing of emergency shutdown valves are essential for ensuring they perform when needed. Unlike control valves, ESD valves are not used regularly during normal operation. They may become stuck or worn out without proper care. It’s important to have a testing and maintenance schedule in place, especially in safety-critical systems.

Partial stroke testing can be an effective way. This is to ensure the ESD ball valve is functioning correctly without interrupting production. This involves testing the valve’s ability to close part of the way. It helps identify potential issues with the valve’s function before a full emergency occurs.

At Gowin Industrial Valve, we offer industry-leading ESD ball valves. They are designed to meet the rigorous safety standards required in industrial applications. Our valves are built with high-quality materials and undergo strict testing.

Why Choose Gowin Industrial Valve?

When choosing an ESD ball valve, it’s essential to work with a trusted manufacturer known for quality and reliability. For over 16 years, Gowin Industrial Valve has been a leader in providing top-tier flow control solutions for industries like oil and gas, chemical engineering, power stations, and water supply. We are certified to meet international safety and quality standards, including:

- API6D

- ISO9001

- ISO14001

- OHSAS45001

- Fire Safety API607 & API6FA

Gowin’s ESD ball valves are designed to offer superior performance in emergency shutdown situations. Our shutdown valves offer the reliability needed to protect your equipment and personnel. They help minimize the risk of accidents.

Emergency Shutdown Valve Response Time

The speed at which an emergency shutoff valve closes can vary depending on the system requirements. Typically, faster shutdowns are preferred, especially in highly volatile environments. Ball valves are among the fastest. They often close within seconds to isolate hazardous situations quickly. In offshore industries, regulations often require that shutdown valves close within 45 seconds to prevent accidents from escalating.

Integration into a Safety System

An ESD ball valve must be integrated into the overall safety instrumented system (SIS). It is not enough to install an emergency valve. Then leave it without consideration for how it fits into the larger process control. A well-designed system will have built-in redundancies and diagnostics. This is to ensure the valve operates when needed.

PFD (probability of failure on demand) calculations help determine optimal testing intervals. They also assess the valve’s reliability. Systems with high safety integrity level (SIL) requirements often use redundant shutdown valves. This ensures that if one valve fails, another can take over.

Final Thoughts

Every aspect of the emergency shutoff valve must be considered carefully. From selecting the right materials to understanding the valve’s response time and integrating it into a larger safety system.

At Gowin Industrial Valve, we provide high-quality, reliable ESD valves that are designed to meet the demands of critical industrial applications. We have extensive experience and certifications. You can trust us to deliver the solutions you need to ensure the safety and efficiency of your operations.