ESD valves (Emergency Shutdown valves) are critical safety components used in industries. These valves are designed to quickly stop the flow of hazardous materials during an emergency. It prevents accidents like explosions, leaks, or overpressure. Since these valves often sit idle for long periods, it’s essential to regularly test them. This is to ensure they work properly when needed.

One way to test ESD valves without fully shutting down operations is by performing a PST test, or Partial Stroke Test. But, what exactly is a PST test, and why is it important?

Let’s explore this in detail.

What is a PST Test?

A Partial Stroke Test (PST) is a method used to check the functionality of an ESD valve without requiring it to fully close or stop the entire process. This test moves the valve to a small percentage of its full range. Typically 10-20%, and verifies that it can still operate smoothly. This is crucial for ensuring that the valve will perform as expected in case of an emergency.

A full stroke test would require shutting down the whole system. A PST test allows the valve to be checked while operations continue. It minimizes downtime. This makes it a popular choice for industries where halting production can be costly and disruptive.

Why is PST Testing Important?

1. Safety: The main goal of any ESD valve is to ensure safety. By performing PST tests, industries can catch potential problems early. This will ensure the valve will work correctly when an emergency occurs.

2. Reduced Downtime: Shutting down an entire system to perform a full stroke test can be time-consuming and expensive. A partial stroke test avoids these issues. It is done by testing the valve with minimal disruption to ongoing processes.

3. Early Detection of Issues: Regular PST tests can identify problems like wear, corrosion, or sticking parts before they turn into major failures. This will save money on repairs and prevent unexpected shutdowns.

How Does a PST Test Work?

During a PST test, the valve is moved slightly from its open or closed position without fully closing or opening. This partial movement is enough to verify that the valve’s actuator, control system, and mechanical parts are functioning correctly.

For example, if an ESD valve is supposed to close fully during an emergency, a partial stroke test will confirm that it starts to close when signaled. This way, you can be confident that the valve will perform its safety function. Most especially when needed without having to stop the entire production process.

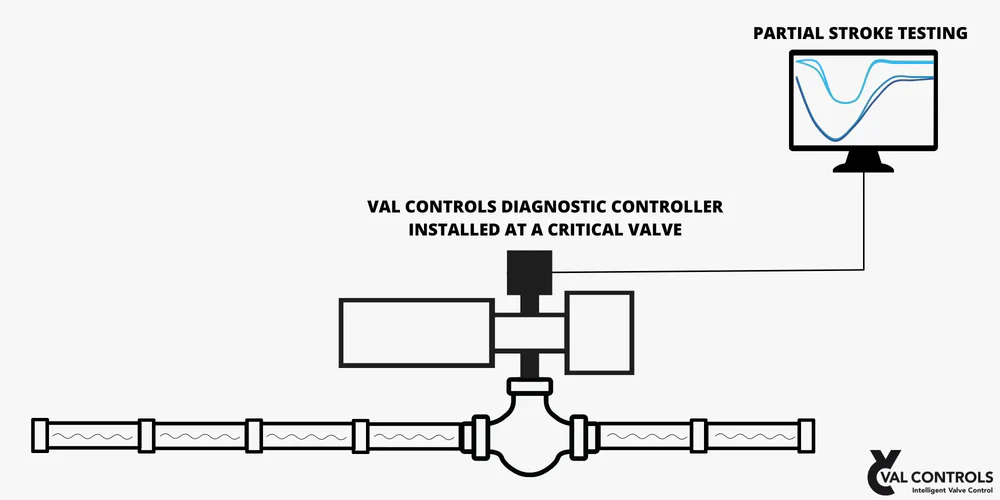

The Role of Modern Technology in PST

Thanks to advancements in valve diagnostics, modern PST testing has become even more reliable and efficient. Many valves now come with digital positioners. It can automatically perform PST tests and monitor the valve’s performance in real time. These digital systems can also alert operators to any potential problems. This makes maintenance easier and more proactive.

Benefits of PST Testing

| Benefit | Description |

| Minimizes Interruptions | Tests valve without full shutdown |

| Enhances Safety | Reduces risk of valve failure |

| Cost-Effective | Detects issues early to avoid costs |

| Regulatory Compliance | Meets safety standards with ease |

Minimizes Process Interruptions

A PST test allows you to ensure valve functionality without a full system shutdown. This keeps production flowing smoothly.

Enhances Safety

Regular testing reduces the risk of valve failure in emergencies. This ensures plant safety and reduces potential hazards.

Cost-Effective Maintenance

By detecting issues early, a partial stroke test helps avoid costly emergency repairs and unplanned downtime.

Compliance with Safety Standards

Many industries have strict safety regulations requiring regular valve testing. PST testing helps meet these requirements without disrupting operations.

Gowin Industrial Valve: A Leader in Flow Control Solutions

When it comes to reliable ESD valves and flow control solutions, Gowin Industrial Valve stands out. Gowin has been a trusted manufacturer of high-quality valves for over 16 years. It is used in industries like oil and gas, chemical engineering, power stations, and water supply.

Gowin’s cutting-edge facility is certified with both local and international standards. These include API6D, ISO9001, and Fire Safety API607 & API6FA. Their products meet the highest safety and performance standards. With their expertise and state-of-the-art manufacturing systems, Gowin provides industry-specific solutions. They prioritize safety and efficiency. Their ESD valves are a perfect choice for any industry where safety and reliability are top priorities.

Conclusion

In industrial settings where safety is critical, ESD valves play a vital role in protecting both personnel and equipment. Regular testing, such as PST tests, ensures that these valves are ready to perform in case of an emergency. This reduces the risk of catastrophic failures.

The PST test is an essential tool for maintaining the reliability of ESD valves. All done without disrupting production. Incorporating modern diagnostic technologies allows for early detection of issues, cost savings, and compliance with safety standards.

For businesses looking for reliable flow control solutions, Gowin Industrial Valve offers a range of high-quality valves. They are designed for safety and performance in demanding environments. With their certified products and 16 years of expertise, Gowin is the go-to choice for industries worldwide.