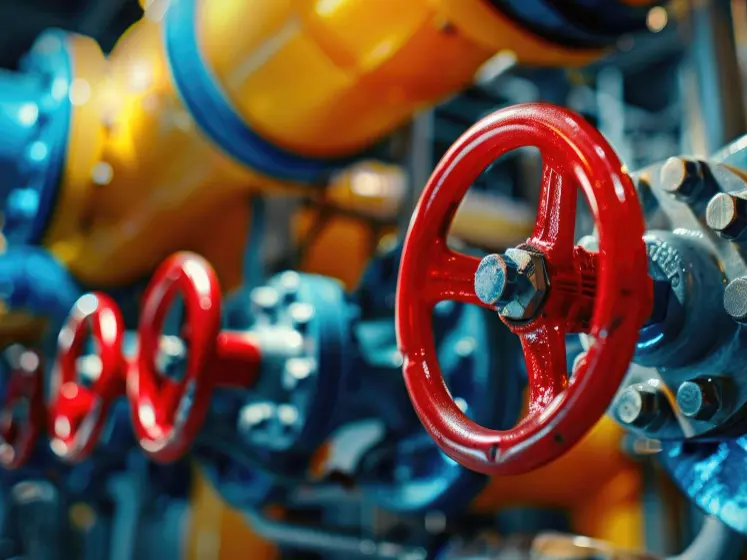

Controlling liquid flow-through in industries is determined by turning of valves which block/allow flow. While all valves open/close, not every kind can be used in all situations. As you read on, you will learn about the distinction between two valves — butterfly valve pneumatic actuator, solenoid valve.

The Differentiation Between Solenoid Valve Actuator And Pneumatic Actuator Butterfly Valve

Functionality Principles

Both solenoid valve actuator and butterfly valve with pneumatic actuator open/close to allow fluid flow. But the way of doing so is different. A pneumatic actuator butterfly valve generates opening/closing movement using compressed air. It follows a 90 degree axis. If the fluid flow goes from left-right, leaving the valve perpendicular blocks flow.

The functionality principle of a solenoid valve can be understood from the solenoid valve definition. The word solenoid links to the concept of electromagnetism. Its structural makeup involves a cylinder coil which covers a moving metallic center. An electric current is passed through the metallic center creating a magnetic force which controls the opening. Once the electric current is stopped, the magnetic field stops and the valve closes.

Actuator VS Solenoid

Actuators and solenoids have differentiable uses. Pneumatic actuators provide the following controlling systems:

- Heating/Cooling

- Air Management

- Fluid Control

A solenoid valve actuator is only responsible for controlling fluid flow.

Uses

A pneumatic actuator butterfly valve is more often found in industry work. These valves handle higher pressures and fluid volumes and can be found here:

- Water Purification Industry

- Chemical Industry

- Food & Beverage Industry

- HVAC Industry

- Power Industry

Solenoid valves are better for situations requiring quick control. These can be found in these industries:

- Automotive Industry

- Refrigeration Industry

Fluid Control

Solenoid valves are better apt for short cycle situations. When valves need to be opened/closed at smaller intervals, the higher fluid stream rates of solenoid valves make them a suitable pick. On the other hand, butterfly valves are suited to higher pressure pipes. These are not endorsed to be used for lower pressure uses.

Prices

Solenoid valves have simpler structural makeup, and so they are cheaper. Butterfly valve with pneumatic actuator will be more expensive due to additional components and a larger structural body.

Maintenance

Solenoid valves require little maintenance due to lower internal components. Any maintenance that needs to be done, can be tended to without requiring special instructions or tools. Butterfly valves are more compounded and more prone to damage. Its maintenance will require attention from a technician.

Final Thoughts

Understanding the basis of Solenoid VS Actuator differences can help you decide which valve to pick. Choosing the right valve depends on your situation, the temperatures, size requirements etc. If you’re still iffy about which valve is more suitable for your needs, reach out to a valves manufacturer like GOWIN Industrial Valve for clarification.