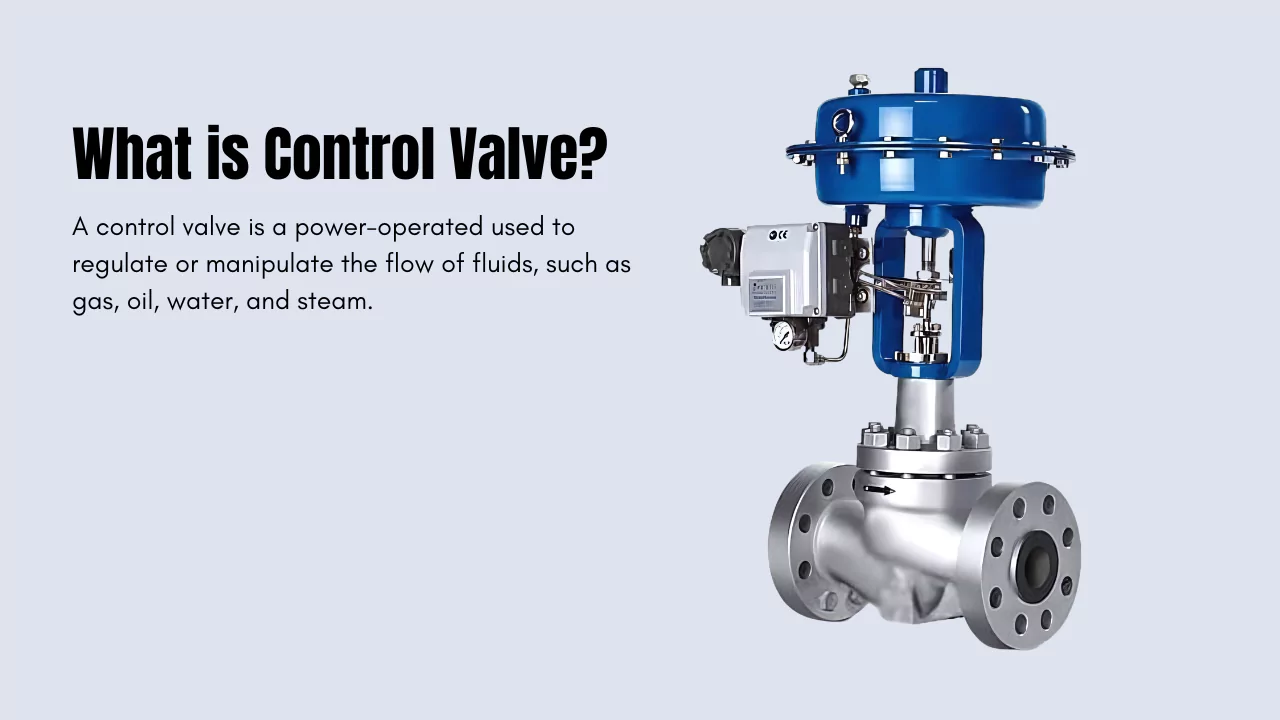

Control valves are essential components in industrial systems. Their tasks involve managing fluid flow, pressure, and temperature. Control valves are also crucial for ensuring safety and operational efficiency across different industries.

In this discussion, we will explore the various types of control valves, their unique applications, and their role in optimizing industrial operations. We will also provide insights into selecting the ideal valve for your needs.

Common Types of Control Valves

Understanding the types of valves and their applications is essential for selecting the right one. Here are some common control valve types:

Globe Valves

Globe valves are ideal for precise flow control. Their linear motion and throttling capabilities make them perfect for systems requiring frequent adjustments. These would include steam or chemical flow regulation.

Butterfly Valves

Butterfly valves excel in low-pressure applications and large-diameter pipelines due to their lightweight design and cost-effectiveness. However, they may not provide as precise control as globe valves.

Ball Valves

Ball valves are primarily used for on-off control. Their tight sealing capabilities and durability make them suitable for high-pressure and high-temperature systems. However, they are less effective for throttling.

Diaphragm Valves

These valves use a flexible diaphragm for precise control and are preferred in sterile or clean applications, such as food and beverage processing.

Plug Valves

Known for their simplicity and resistance to clogging, plug valves are ideal for handling viscous fluids or slurries. Examples are industries like petroleum refining.

Flow Control Valves: What Are They?

A flow control valve is also called a regulating valve. It adjusts the rate of fluid flow in a system. These valves are crucial in processes requiring stable and accurate control of liquid or gas flow.

A pneumatic flow control valve is a combination of a valve and an actuator. This type of control valve uses compressed air to regulate flow. The design enables fast response times and high precision, making it ideal for automated systems.

Technically, a flow control valve regulates flow rate, which can indirectly influence pressure within a system. By restricting fluid movement, the valve can create a pressure drop upstream.

However, its primary function is not pressure reduction but rather flow management. If pressure regulation is a requirement, specialized pressure-reducing valves should be considered alongside flow control valves.

How to Choose the Right Control Valve

Selecting the right valve depends on several factors, including application, operating conditions, and fluid type. Here are some key considerations:

- Application Needs: Evaluate whether you need precise flow control, on-off functionality, or contamination prevention. For instance, diaphragm valves are excellent for sterile environments. On the other hand, ball valves are ideal for high-pressure on-off control.

- Fluid Type: Corrosive fluids, viscous slurries, or clean gases all require different materials and valve designs. Plug valves excel with abrasive fluids, while butterfly valves suit water distribution systems.

- Operating Conditions: Consider the pressure, temperature, and flow rate in your system. For example, globe valves are better for high-pressure systems requiring fine flow adjustments.

- Actuator Type: A pneumatic flow control valve is a combination of a valve and an actuator. Pneumatic actuators are best for quick, frequent adjustments. Electric actuators offer precise, automated control.

Gowin’s Control Valves: The Trusted Choice

Gowin manufactures a wide range of control valves tailored to meet specific industrial needs. Their valves, built to international standards, ensure durability and high performance in demanding environments. Whether you need a ball valve for a high-pressure system or a butterfly valve for large pipelines, Gowin delivers solutions with unmatched quality and reliability.

Conclusion

Control valves are the backbone of industrial systems. They regulate flow, pressure, and temperature with precision. Choosing the right valve—whether globe, ball, or butterfly—can transform efficiency and safety.

For over 16 years, Gowin has delivered reliable, high-performance valves. Built to global standards, Gowin valves meet the toughest demands. Trust Gowin for durable, efficient flow control solutions that keep your operations running smoothly.

Frequently Asked Questions

Can butterfly valve be used for flow control?

Yes, a butterfly valve can be used for flow control. However, it is typically more effective for low-pressure systems or on-off applications. For precise flow adjustments, a globe valve may be a better choice.

Does a Flow Control Valve Reduce Pressure?

While its primary function is to regulate flow, it can cause a pressure drop upstream as it restricts the fluid flow.

What are some certifications that indicate a high-quality control valve?

High-quality control valves meet certifications such as:

- API6D: Pipeline valve standards.

- ISO9001: Quality management.

- ISO14001: Environmental management.

- OHSAS45001: Occupational health and safety.

- Fire Safety: API607 & API6FA compliance.

Gowin adheres to these standards, ensuring reliable and durable products.

What is the difference between a globe valve and a ball valve?

Globe Valves: Provide precise flow control and are used for throttling applications.

Ball Valves: Best suited for on-off control, especially in high-pressure systems, but less effective for throttling.

References

Gas Well Deliquification A volume in Gulf Drilling Guides; James F. Lea, Jr and Lynn Rowlan; 2019 (https://www.sciencedirect.com/book/9780128158975/gas-well-deliquification)

Applied Process Design for Chemical & Petrochemical Plants; Ernest E Ludwig; 1999 (https://www.sciencedirect.com/bookseries/applied-process-design-for-chemical-and-petrochemical-plants)