Table of Contents

ToggleThere are numerous flow control valve types, including check valves, gate valves, butterfly valves, pinch valves, diaphragm valves, and ball valves.

However, picking the improper flow control valve from the numerous options available can be intimidating.

Our experience as a top manufacturer can help you better comprehend the six flow control valve types listed above.

So, read on to learn more and assess if they match your needs.

6 Flow Control Valve Types

- Ball Valves

Operation

This is among the flow control valve types that use a ball with a central hole.

The ball rotates 90 degrees to align the hole with the flow route, allowing the medium to pass through.

Letting the ball’s solid part to face the path enables it to block the passage, making it simple to use for both on and off applications.

Some Applications

These flow control valve types are usually used in high-pressure systems that require immediate shut-off capabilities, like the automotive industry and HVAC systems.

This Flow Control Valve Types Advantages and Disadvantages

| Advantages | Disadvantages |

| Low maintenance | Not appropriate for slurries. |

| Low-pressure drop | Vulnerable to blockages from thick media. |

| Quick shut-off capabilities | Throttling is generally not recommended unless it has a V-port ball valve. |

Operation

They’re shut-off devices that control the flow of liquids or gases through sliding the vertical disc up or down.

It allows the medium to pass through with little resistance, resulting in minimal pressure loss and blockage.

If it is manual, you must typically rotate the handwheel or actuator more than 360 degrees clockwise before the stem attached to the disc lowers towards the seat.

This completely blocks the flow path and ensures tight sealing.

Turning it counterclockwise for an entire 360 degrees raises the disk, allowing the medium to flow through.

Some Applications

Often used for low-pressure applications that do not really require precise flow control, such as water delivery systems.

This Flow Control Valve Types Advantages and Disadvantages

| Advantages | Disadvantages |

| Tight Sealing | Not suitable for throttling. |

| High flow rate. | It can only be totally open or entirely closed. |

| Can block flow both upstream and downstream. | Because the actuator must rotate 360 degrees, it opens and closes slowly. |

- Pinch Valves

Operation

They use a flexible tube, which is squeezed shut to block the flow channel until it can be released again.

The pinching mechanism used to push the two sides of the tube together can be pneumatic, mechanical, or hydraulic.

Hydraulic fluid can be used for hydraulic check valves, whereas pneumatic types use compressed air.

While a pinch bar is utilized if it’s mechanical and controlled by a handwheel or screw mechanism.

Here is a YouTube video to assist you in better understanding how they work.

This Flow Control Valve Types Advantages and Disadvantages

These flow control valve types can effectively handle slurries or abrasive materials, making them ideal for industries that require minimal contamination, like wastewater treatment plants.

However, they have limited durability due to flexible tube material susceptibility to wear.

Operation

Among the flow control valve types, this is also referred to as non-return or one-way valves because it allows fluids or gases to flow in just one direction.

They open when the force or cracking pressure from the upstream is sufficient to elevate the disc inside the valve, allowing media to pass through.

If the pressure drops or the flow turns around, the disc closes itself to avoid backflow.

Here’s a YouTube video showing how they function.

Some Applications

These flow control valve types are suitable for water pipelines, heating systems, and industrial operations such as petroleum and chemicals.

This Flow Control Valve Types Advantages and Disadvantages

| Advantages | Disadvantages |

| Stop Backflow | Chattering |

| Low maintenance due to the few components. | Water hammering |

| It saves energy because it does not require any additional power to work. | Limited Flow Control |

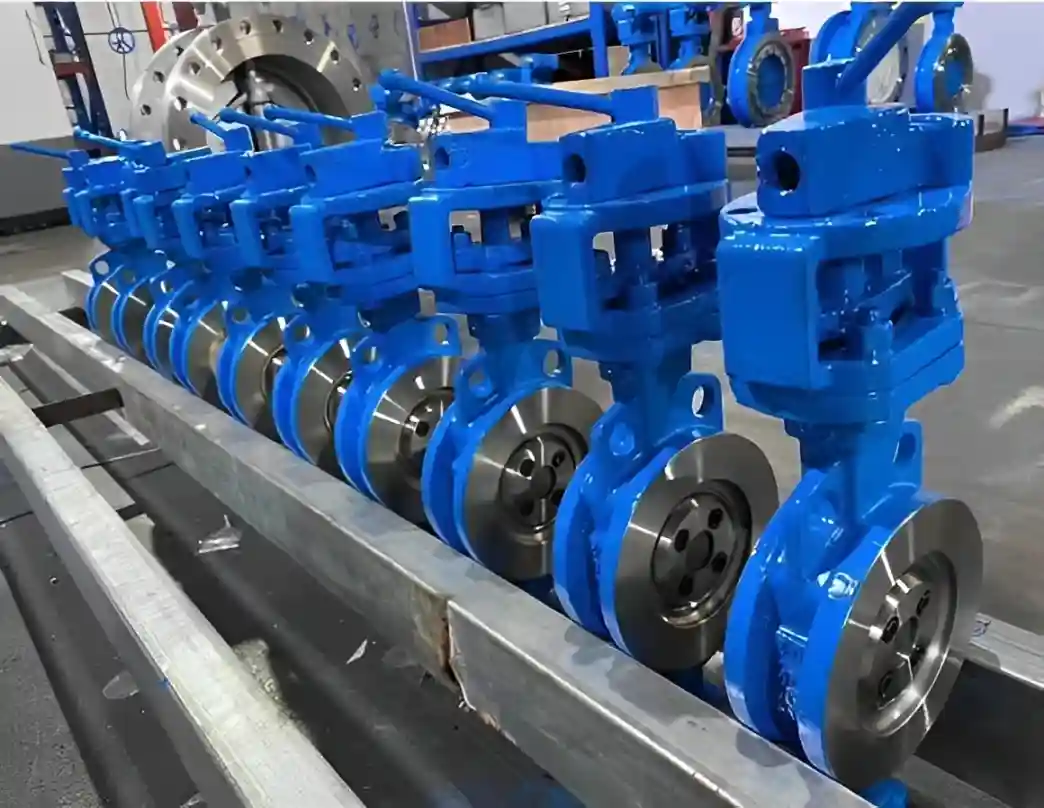

- Butterfly Valves

Operation

It features a vertical disc that spins at 90 degrees to either stop or allow fluid to flow through, making it simple to open and close.

The actuators connected to the disc can be controlled manually, electronically, or pneumatically.

Some Applications

Chemical or agricultural industries with low to medium pressures and temperatures, as well as applications requiring clean fluids like water distribution systems.

This Flow Control Valve Types Advantages and Disadvantages

| Advantages | Disadvantages |

| Compact structure | Prone to choked flow |

| Lower pressure drop | Not suitable for use with strong or corrosive fluids. |

| Quick to open and close | Not generally recommended to always use for precise throttling. |

- Diaphragm Valves

Operation

Also one of the flow control valve types uses a flexible item either to block or let the medium flow through it.

A stud is connected to a flexible diaphragm, which attaches to the plunger and stem, causing it to close or open the valve.

If it’s manual, you must turn the handwheel counterclockwise slowly to raise the diaphragm and clockwise to lower it.

Some Applications

They are also ideal for mild temperature and pressure settings and are commonly used in industries that deal with corrosive mediums, such as chemical or pharmaceutical manufacture.

This Flow Control Valve Types Advantages and Disadvantages

| Advantages | Disadvantages |

| Simple maintenance | The flexible diaphragm are vulnerable to wear |

| Low Pressure Loss. | Not appropriate for applications requiring high flow rates. |

| Can handle both dense and hazardous liquids. | Minimal pressure ability makes them unsuitable for high pressure. |

Control Valve Types’ Certifications: What standards are used for valves?

Flow control valve types had to follow several standards to be deemed reliable and safe for use in a specific industry or application.

Here are some of them to watch out for when purchasing a flow control valve:

| Standards/Certifications | Primary Industry/Application | Importance |

| American Petroleum Institute Certifications (e.g API 641, API6D, API607) | Oil and Gas | It focuses on ensuring that equipment such as valves, can endure high pressures effectively and safely. This reduces the risks associated with poorly manufactured parts within the industry’s systems. |

| Food and Drug Administration Certification (e.g, 21 CFR 177.1550) | Food and pharmaceutical | It confirms that valves are safe to use with food or medicines. Complying with this standard reduces infection risks during production operations, guaranteeing consumer health. |

| National Sanitation Foundation Certifications (NSF/ANSI 61 and NSF/ANSI 372) | Food, beverages, and drinking water | It is evaluated if the valve complies with whether the valve meets rigorous health and safety standards in food, beverage, and water quality systems. Valves with these certificates confirm that their materials do not contain hazardous chemicals or lead. |

Source:

Ball Valves: Advantages and Disadvantages

Insights on Application of Check Valve Uses

What are the advantages and disadvantages of gate and diaphragm valves?