Table of Contents

ToggleThe American Petroleum Institute has developed a standard of API 6D which is a certification specifically for pipeline valves. Through this API certification, the assembly, design and testing of valves in the oil and gas industry is regulated. It also ensures that the API 6D valve testing is done thoroughly and that the pipelines are seen as reliable and secure. This allows for the valves to be globally recognized and meet the standards of companies operating in these industries.

The History Of Certifications

ASME or the American Society of Mechanical Engineers develop not only the codes but even the API 6D standards for future use. This organization looked to promote safety and efficiency in anything related to mechanical engineering. After WWII, API 6D was introduced just for valves as the oil industry experienced significant growth. Nowadays, without ASME certification a valve’s integrity is questionable and is not considered due to safety precautions.

The Basis Of API 6D Standard

So what is API 6D standard? As mentioned before, it centers on pipeline valves involving gate, plug and ball types. Furthermore, there are material specifications such as metals and alloys to ensure durability and suitability for any operating environment. These valves are also designed to withstand various temperature ranges depending on their use anywhere.

API 6D standard requires rigid quality control like supervising the production process and even verifying the materials used. This process is also documented through API 6D certificates and inspection reports. Since these valves are used for oil and gas transportation systems, API 6D provides recommendations for proper installation and maintenance of valves that ensures effectiveness over long distances.

Types Of API Certification

API 6D

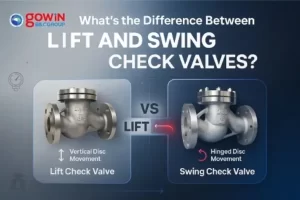

The API 6D standard primarily focuses on gate, plug, check and ball valves with certain material specifications for durability in various operating environments. This standard establishes the blueprint for the design and manufacturing of these parts.

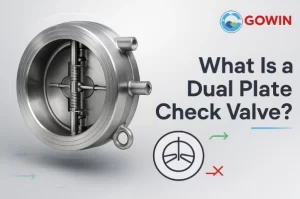

API 594 VS API 6D

API 594 is limited to check valves like dual-plate and wafer-type, while API 6D covers a broader range of valves as mentioned above. API 594 allows for a more compact design while API 6D requires accurate testing to make sure that the valves are suitable for use.

API 598 VS API 6D

API 598 is mainly involved with the quality control of valves guaranteeing that they meet leakage and operational criteria through testing. In addition, API 598 does not need the extensive documentation that API 6D demands.

API 600 VS API 6D

API 600 valves are mostly used in processing facilities where control over the flow of fluids within the plant is required. API 6D is used for longer distances and on a larger scale. API 600 concentrates on steel gate valves due to higher pressure/temperature environments.

API 608 VS API 6D

API 608 focuses remotely on metal-seated ball valves which are designed for severe service conditions. For this reason, it is used in higher pressure/temperature situations. In comparison to this, API 6D covers a wider range of valves.

Final Thoughts

API 6D is a certification developed for pipeline valves to ensure their safety, reliability and meeting the standards of companies operating in these industries. With the various valves under API 6D domain, it can provide the correct maintenance and installation methods for smooth and efficient operations in the future.